Build before you build: Why does marketing come first in modular Home plant optimization?- SCG Sourcing supply chain

The dream of building a new modular building factory is exciting

Innovation, efficiency and the promise of reimagining the way homes and buildings are constructed have captured the imagination of factory owners and investors alike. But before the first steel beam is welded, before the first modular unit comes off the line, there is one crucial step that is often overlooked: marketing. Yes, marketing – not plant layout, not line automation, not even location – marketing is the key to success. Here’s why.

Marketing shapes the blueprint

Imagine you design a factory to produce high-end luxury modular homes, only to find that your target market needs affordable labor housing. Market research should serve as a compass to guide plant design and operation. With a deep understanding of your audience’s needs, preferences, and willingness to pay, you can align your production capabilities with market demand from day one.

Consider these questions:

Who are your target customers? Are you serving developers, custom home buyers, or government-funded housing projects?

What is your Unique Selling Point (USP)? Are you offering speed, customization, sustainability, or affordability?

Where is the demand concentrated? Is your factory location best suited to reach these customers?

Without clear answers, you run the risk of building a plant optimized for a market that doesn’t exist, or worse, missing out on profitable opportunities.

Putting the cart before the horse: The mistake of factory-first thinking

Some modular entrepreneurs dive headlong into the technical details of production without thinking about who will buy their product or why. They invest in state-of-the-art machinery and robotics, only to find that their fancy equipment is not suitable for the houses or buildings that the market demands. For example, a factory that aims to mass-produce square modules may struggle to transform if the market shifts to unique custom designs. If you don’t take a marketing-first approach, you could end up with a technologically advanced but strategically misaligned plant.

Build brand awareness first

The reputation of a modular plant does not begin on the day of its opening -it begins months or even years before it opens. Early marketing efforts create buzz, attract investors, and build credibility. By the time your plant is operational, your brand should already be a well-known brand in the industry.

How to build awareness before a product launch:

Social media influence: Share the latest on plant progress, innovative ideas and industry insights. Platforms such as LinkedIn and Instagram are very useful for connecting with B2B and B2C audiences.

Website Development: Create a professional website that clearly communicates your mission, product offerings, and unique approach

Industry networking: Attend trade shows, participate in panel discussions and network with industry leaders to position yourself as an expert.

Ensure pre-sales and partnerships

Pre-sales strategy: Rendering and Prototyping: Use 3D renderings, virtual reality walkthroughs, or small-scale prototypes to present your vision.

Strategic partnerships: Work with developers, architects and contractors to ensure a steady demand for your products.

Flexible contracts: Offer customizable agreements that incentivize early commitment while giving customers room to adjust.

Marketing determines the factory’s mission

In addition to manufacturing modules, each modular factory needs to take on a mission. Marketing helps clarify the identity of the plant and becomes a guiding light for decision making. Are you the “Tesla” of modular construction, innovating with cutting-edge materials and technologies? Or is it the “Ikea” of modular housing, offering affordable, fully functional units on a large scale? This identity determines everything from product line design to employee recruitment and customer service. Without a clear marketing mission, factories tend to drift along and try to be all things to all people, which often means they won’t be great at anything.

Coordinate marketing and operations

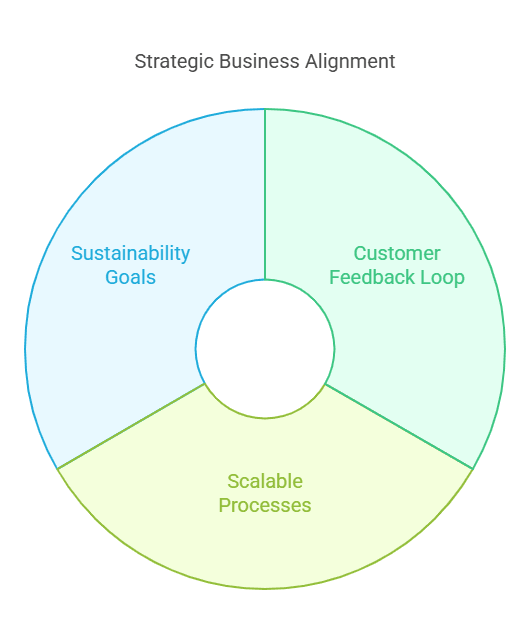

Optimizing modular factories is not just about efficiency, but also about producing the right product efficiently. Marketing and operations must work together to achieve this balance. The method is as follows:

Customer feedback loop: Before opening, collect feedback from potential customers on design, materials, and pricing. Adjust production capacity accordingly.

Scalable processes: Design production lines that can adapt to market changes. For example, if your market research indicates growing demand for ADUs (attached residential units), your factory should be able to easily transition to producing them.

Sustainability Goals: If your marketing emphasizes going green, make sure your operations align with sustainable practices, from sourcing materials to energy-efficient manufacturing.

Avoid Marketing pitfalls

Marketing first does not mean marketing only. Balance is key. Some common pitfalls include:

Overpromise: Don’t promise delivery schedules or customization options that your factory can’t actually achieve.

Ignore operations: Marketing can set the vision, but operations can turn it into reality. Make sure the two teams communicate regularly.

Neglect aftermarket marketing: Customer referrals and case studies are critical to building long-term success

Building modular factories is a difficult task, but success is based not on concrete or steel, but on strategy. And the core of strategy is marketing. By prioritizing market research, brand building, and customer engagement from the start, you can set the stage for a plant that will not only optimize production, but hopefully turn a profit. So, break into your market before you break ground. Learn about it. Get involved. And build your factory around it. Only then can you truly optimize your modular factory for success.